SteelCalc®: New Steel Inspection Techniques & Criteria Analysis

SteelCalc®: New Steel Inspection Techniques & Criteria Analysis

Historically, the below-grade structural condition of steel transmission assets has been evaluated by a combination of visual observation of structural damage and the collection of thickness measurements. This assessment is performed to determine the below-grade foundation structural condition to ultimately evaluate risk and prioritize mitigation and structural restoration.

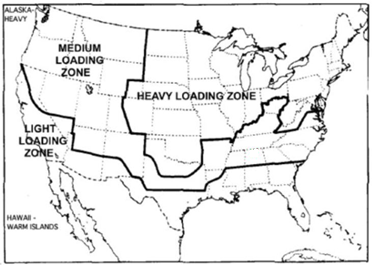

The most basic groundline condition rating system is a visual assessment only, which is an ineffective and outdated practice. The most common inspection process in the electric transmission industry is the physical measurement of visually identified corrosion to classify the structural condition at groundline. Osmose Steel-Calc® offers an improved assessment by incorporating physical and structural characteristics beyond basic member section loss and far beyond a solely limited visual inspection. Some of the variables used in the Steel-Calc analysis include steel tower and pole geometry, structure loading and utilization, geographical location, and structure-specific identifiers such as circuit information, line angle, and number and size of conductors.

While some of this information can be acquired from the utility source data, the majority of data is collected during the field inspection. The analysis of so many specific features and variables enables more accurate prioritization of deficient or deteriorated members and structures and, in turn, allows for more targeted restorations and optimization of the utility’s resources.

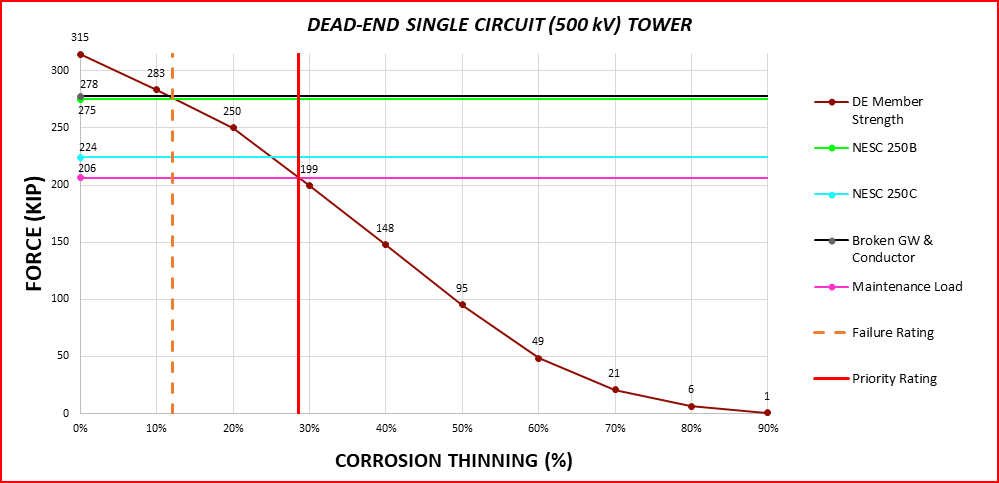

This new inspection protocol analyzes more structure-specific data, which is compared against industry standards to provide the most accurate and economical results. The process begins by inputting visual inspection data, measurements, geographical location, and structural characteristics. These inputs are analyzed and compared against the National Electrical Safety Code (NESC) load combinations and utility-based load cases. Common industry load cases include: NESC 250B – Ice and Wind, NESC 250C – Extreme Ice, and NESC 250D- Extreme Ice with Concurrent Wind. Common utility-based load cases can include factors such as broken conductors and/or ground wires as well as maintenance loading.

This new inspection protocol analyzes more structure-specific data, which is compared against industry standards to provide the most accurate and economical results. The process begins by inputting visual inspection data, measurements, geographical location, and structural characteristics. These inputs are analyzed and compared against the National Electrical Safety Code (NESC) load combinations and utility-based load cases. Common industry load cases include: NESC 250B – Ice and Wind, NESC 250C – Extreme Ice, and NESC 250D- Extreme Ice with Concurrent Wind. Common utility-based load cases can include factors such as broken conductors and/or ground wires as well as maintenance loading.

Following the characteristic and loading zone input, the reaction, or load, for each component is calculated for each loading combination. Steel-Calc® analyzes the data and displays the vertical reaction for each component under the various load combinations. After load calculations are made, the strength of each structure is measured against any external loads. To complete the analysis, the external loads are then directly compared to the determined load capacity of the steel member as shown in the following example.

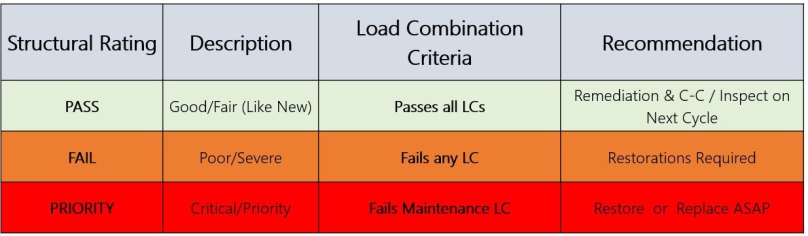

Once the analysis is complete, a specific rating can be assigned based on the condition rating system below to prioritize restorations.

The updated steel condition rating system builds on the existing, thinning measurement only rating system by taking additional measurements and structure-specific variables to more thoroughly prioritize structure risk. Structures that fall within the critical/priority range will receive the highest restoration priority, followed by structures that fall under the poor/severe category. This improved assessment protocol benefits utilities by providing them a targeted and precise plan of action with more accurate priority ratings. The improved inspection and structural analysis protocols ensure accurate condition ratings while expediting capital budget allocation to the most at-risk transmission structures. This more detailed structural analysis arms asset managers and engineers with the best information possible, enabling them to choose the appropriate next steps to extend the life of these critical assets. Ultimately, this improved structural condition analysis will save the utility time and resources because the right structures can be restored at the right time.

For more information, contact your Osmose professional or steel@osmose.com.

.png?width=243&name=Osmose-logo-(white).png)