NeighborPlate: Universal Solution to Steel Pole Restorations

Steel transmission poles are among the most challenging structures to properly restore. Typical transmission poles are tapered and multi-sided (polygonal) which, along with manufacturing tolerances, results in variability from pole to pole. In other words, every pole is unique, and the dimensions change along the length of the pole. As a result, many design, fabrication, and installation challenges become magnified and must be accounted for when repairs are performed with traditional methods.

Steel transmission poles are among the most challenging structures to properly restore. Typical transmission poles are tapered and multi-sided (polygonal) which, along with manufacturing tolerances, results in variability from pole to pole. In other words, every pole is unique, and the dimensions change along the length of the pole. As a result, many design, fabrication, and installation challenges become magnified and must be accounted for when repairs are performed with traditional methods.

Traditional repair methods, such as bent plate collars or sleeves, can produce mixed results. Repairs can have significant fit-up issues and, sometimes, not fit at all. This is due to the variability of poles and the complexity involved with making a custom, perfectly matching set of plates for a specific elevation on a pole. In addition to the more obvious issues from poor fit-ups, understrength weld joints can also occur from excessive joint gaps. Given the critical role of the welds, which connect the repair to the pole, this can result in deficient repairs with unacceptable risks.

The patented NeighborPlate restoration system, invented by Professional Engineer and Certified Structural Welder Kristopher Neighbor, has the unique ability to accommodate varying pole flat widths. As such, the system overcomes many impediments to proper pole restoration fit-up, including pole taper and manufacturing tolerances.

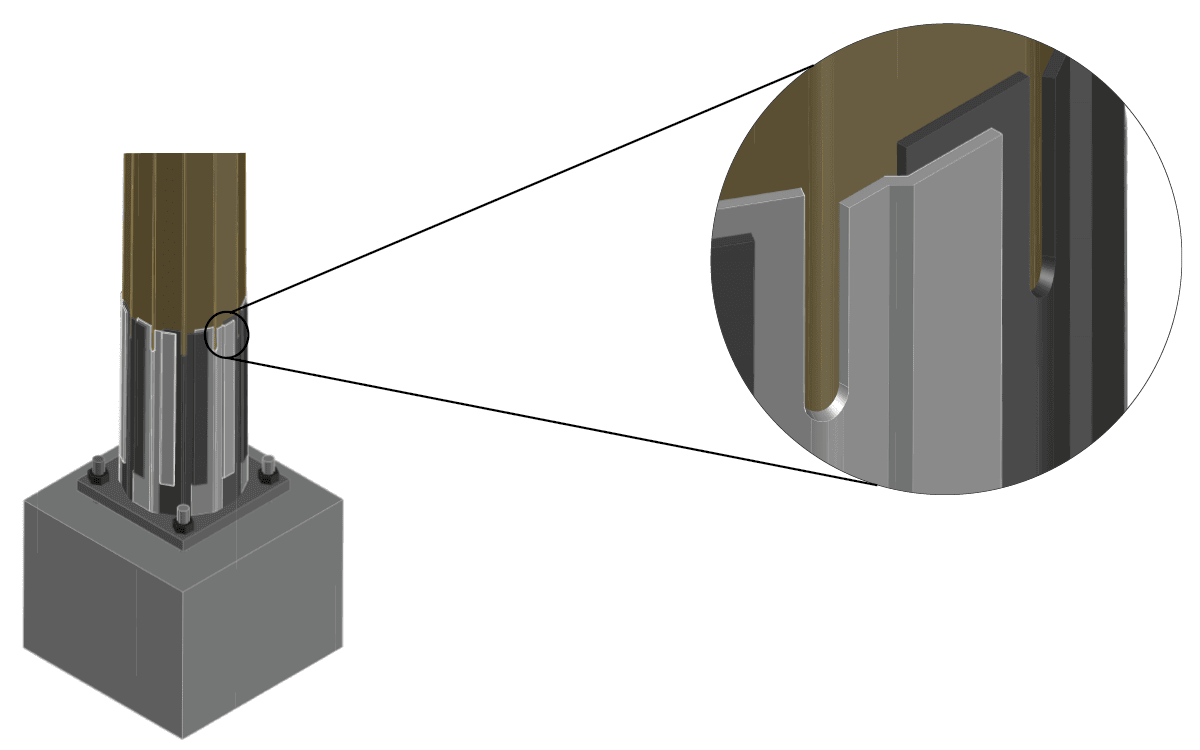

Made from the same high-strength structural steels typical for new poles, the NeighborPlate system is a welded restoration consisting of specially formed plates with lap joints that adjust to the variable flat widths of a pole. These lap joints enable the NeighborPlates to consistently fit-up to each tapered pole, which minimizes gaps for quality weld joints. While the lap joints allow good fit, the ends of the NeighborPlates have a special profile to provide the necessary weld strength for load path and force transfer between the pole and restoration. As a result, the system can restore original strength to poles with localized damage from corrosion or other causes.

Since it is nearly identical to the existing pole geometry, much of the engineering behind the NeighborPlate system referenced industry standards including, ASCE/SEI 48, Design of Steel Transmission Pole Structures and applicable portions of AWS D1.1, Structural Welding Code - Steel. Performing Finite Element Analysis (FEA) provided further insight on how the loads on a pole are transferred and distributed through the NeighborPlate system. FEA also verified the areas of highest to lowest theoretical stresses, which enabled further optimization of the design.

The versatility of the NeighborPlate system provides a consistent, repeatable restoration which is typically performed without service interruption. This restoration system can be used on self-supported or guyed, direct-embedded poles, base plate mounted poles, as well as frame-type structures (H-frames, etc.). NeighborPlates used for direct-embedded poles have the same profile at both the top and bottom of the restoration. While the top profile is the same, NeighborPlates used on base plate mounted poles have a different bottom profile for complete joint penetration welds to the base plate and bottom longitudinal joints.

The versatility of the NeighborPlate system provides a consistent, repeatable restoration which is typically performed without service interruption. This restoration system can be used on self-supported or guyed, direct-embedded poles, base plate mounted poles, as well as frame-type structures (H-frames, etc.). NeighborPlates used for direct-embedded poles have the same profile at both the top and bottom of the restoration. While the top profile is the same, NeighborPlates used on base plate mounted poles have a different bottom profile for complete joint penetration welds to the base plate and bottom longitudinal joints.

The NeighborPlate system is adaptable for other applications and is not limited to pole restorations. For example, the system can provide supplemental protection to undamaged poles containing areas vulnerable to damage. This includes hardening areas of a pole vulnerable to mechanical damage or creating a ground sleeve replacement for additional corrosion protection.

In 2019, Osmose performed over 100 installations of the NeighborPlate system on steel poles throughout the United States. Its unmatched capabilities have made the NeighborPlate the leading solution for steel pole restoration on utility systems at a significantly lower-cost than structure replacement.

For more information about NeighborPlate steel pole restorations, contact your local Osmose representative or email steel@osmose.com.

Representative examples of direct-embedded poles at various stages of the NeighborPlate restoration process.

.png?width=243&name=Osmose-logo-(white).png)