Using Pole Solver for Overloaded Poles

O-Calc Pro is a pole loading software designed to inform the user of pole failure, which is the result of a pole being overloaded. An overloaded pole has a capacity utilization value that exceeds 100%. This means that the load being applied to the pole exceeds the amount that the pole can support. There are many factors influencing whether or not a pole will fail. It is sometimes the case the a pole is modeled exactly as it exists in the field, and it shows that it is failing. How can this be, when it is standing in the field? This may suggest that after some amount of time, the pole will fail.

One solution that can be performed prior to pole failure, would be to change the pole out, usually for a higher-class pole. This solution can also be applied to proposed work, where substituting in a larger pole may allow for additional attachments to be placed on the pole. On common difficulty with changing out pole classes is to know exactly what class is needed to ensure that the pole is passing. One method that can be used in the O-Calc Pro software is the use of the Pole Solver, an option that suggests a pole size to a user and estimates what the new capacity utilization of the pole would be.

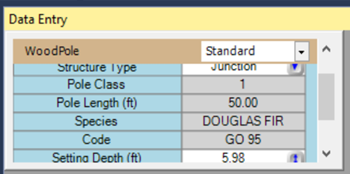

To begin with, a user would have an overloaded pole. Below I have a pole that is overloaded to about 136%.

This pole happens to be a 50 ft, class 1 pole.

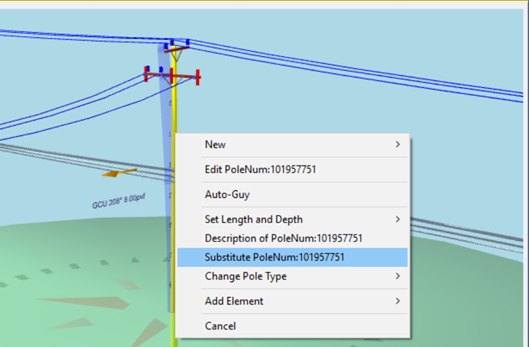

If it is not possible to guy this pole, the only solution may be to replace it with a larger class pole. To determine what class pole I should use, I can begin by right-clicking on the pole, and selecting the “Substitute Pole” option.

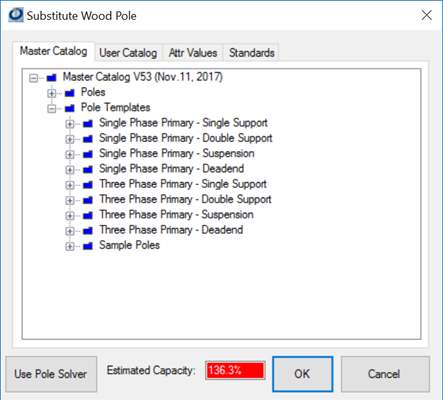

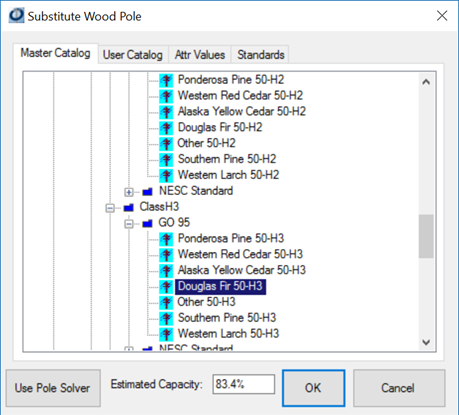

This will open the pole substitution panel.

In this window, the current pole’s estimated capacity is shown. By selecting the “Use Pole Solver” button in the bottom left-hand portion of this window, a new pole will be selected for me that is not failing.

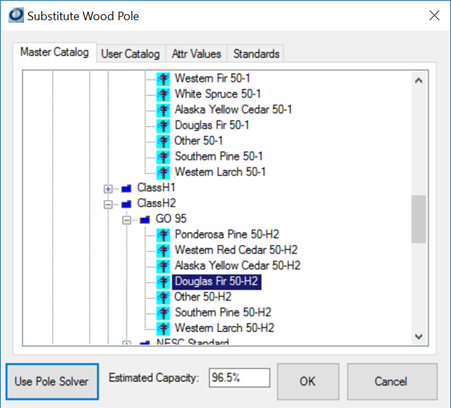

When I selected the “Use Pole Solver” Option, the tool selected a 50 ft class H2 Doug fir pole as the solution. By using this size pole, by new capacity would be 96.5%, and would technically be passing.

Now, if I wanted to ensure that I had more room on my pole for additional attachers, I could choose another larger pole, and see an estimated capacity for my selection. So, if I were to instead choose a 50 ft class H3 Pole, my new capacity would be shown.

Choosing this size would ensure that I was passing, but not as close to failing again as I would have been with the H2 class.

Using the Pole Solver option, or experimenting with different pole classes allows a user to see the best solution prior to actually performing the pole substitution.

.png?width=243&name=Osmose-logo-(white).png)