Drone Inspection in Underground High-Voltage Transmission Vaults

Combined with decades of vault inspection (assessment) experience, Osmose utilizes industry-proven, remote, non-destructive technology to safely assess the integrity and reliability of underground vault systems. .jpg?width=418&height=314&name=UAV%20Drone_1%20(1).jpg) Osmose FAA-certificated drone pilots work in tandem with field vault technicians to capture specific Points of Interest (POI) to provide timely and accurate assessment reporting, data, and imagery.

Osmose FAA-certificated drone pilots work in tandem with field vault technicians to capture specific Points of Interest (POI) to provide timely and accurate assessment reporting, data, and imagery.

Often referred to as drones,Uncrewed Aerial System (UAS) assessments ensure regulatory compliance while providing accurate and timely reporting and condition prioritization for mitigation. UAS underground vault assessments increaseefficiency as they are often performed in a fraction of the time it takes a professionally trained technician to perform similar work. These assessments also allow the vaults to remain energized while high-definition infrared cameras and LiDAR sensors capture images without sacrificing safety.

UAS Assessment Mapping & Points of Interest & Mapping

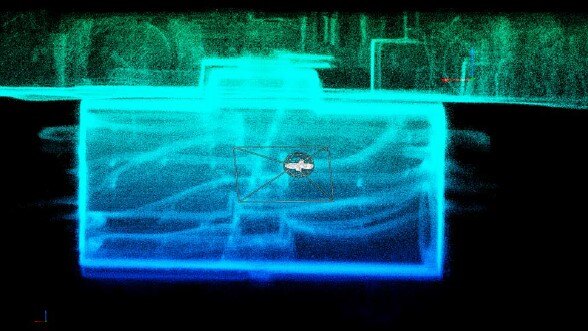

Osmose drones are outfitted with LiDAR sensors to deliver mapping capabilities, providing an accurate 3D point cloud of the vault and vault components. The assessment mapping allows utilities to collect vital POIs, including:

- Interior Condition: Our drones provide real-time, detailed visual data of the vault’s interior by entering the confined spaces while capturing video and still images of the overall condition of the vault environment. They can identify signs of flooding, leaks, damage, or other issues like pest infestations that can affect the vault’s operation.

- Structural Integrity: Drone sensors capture structural element conditions including walls, ceilings, and support members. This identifies cracks, concrete delamination, voids, and signs of physical wear that could compromise the vault’s integrity. Because LiDAR maps the space in three dimensions, it offers detailed insight into structural condition and integrity that the human eye cannot often detect.

- Corrosion: Our drones capture signs of corrosion on metal surfaces within the vault.

- Cable Positions: The drone's cameras, combined with real-time data transmission, can assess the arrangement and position of electrical cables within the vault. With visibility from various angles, the drone provides a clear visual map of how cables are routed, making it easier to detect any misalignment or sagging.

- Cable Splices: Our drones capture cable splice conditions using high-definition cameras to determine their physical condition while infrared sensors capture hot spots, identifying potential failure points before they occur.

Underground Vault Drone Inspection Safety

The use of drones in underground electrical vaults is generally safer than traditional methods for three primary reasons:

- Reduced Human Exposure: Using drones minimizes the need for humans to enter potentially dangerous underground electrical vaults, reducing the risk of accidents, electrocution, and exposure to hazardous gases and contaminants.

- Enhanced Visibility and Access: Traditional assessment is often limited by the physical and visual obstructions within the space. Our drones, however, are equipped with high-resolution cameras, LiDAR sensors, and even thermal imaging, allowing technicians to see areas that are hard to reach or poorly lit with a higher degree of clarity and without putting themselves at risk.

- Cost Efficiency: Because drones can assess vaults more quickly and safely, they often reduce the need for costly safety precautions like ventilation setups, protective gear, or multiple workers, leading to both safer and more efficient operations.

Through the use of Uncrewed Aerial Systems, utility companies can significantly enhance assessment accuracy and efficiency while maintaining a high level of safety.

.png?width=243&name=Osmose-logo-(white).png)